WELCOME TO SILMEK

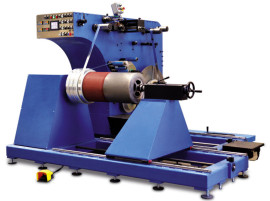

Our company produces winding machines and systems and acts as a subcontractor for the supply of resin transformer coils for firms that have to urgently complete orders or solve problems related to unexpected increases in production. We generally provide services to clients seeking high-quality components.

The members of our technical staff have about twenty years of experience in this sector and we are fully aware of current expectations in terms of construction features and the provisions of regulations relating to cast-resin transformers from 10 kVA to 10 MVA.

Our production plants make use of advanced technology, such as that found in our programmable winding machines and resin-casting systems with constantly monitored

and controlled operational parameters.

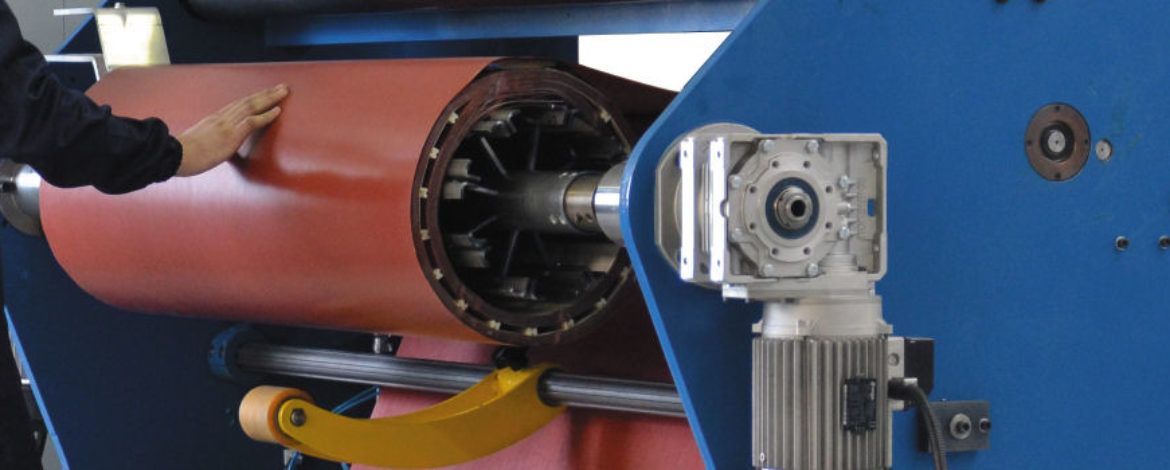

STRIP WINDINGS

▸ Aluminium or copper strip-type windings▸ Automatic horizontal winding machines

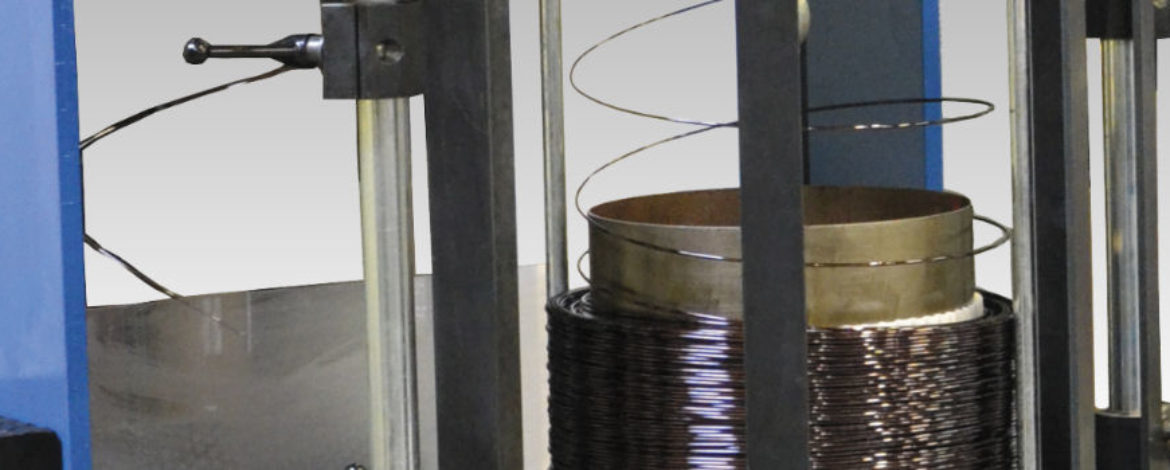

WIRE OR RECTANGULAR WIRE-TYPE (FLAT) WINDINGS

▸ Wound copper or aluminium rectangular wire -type windings▸ Enamelled copper or aluminium wire windings

▸ Concentric vertical coiling technique

FOIL-TYPE WINDINGS

▸ Automatic horizontal-winding machines▸ Aluminium or copper plate-type windings

Production

We use state-of-the-art technology for our high-quality products.

High professional standards

Our technical staff have twenty years of experience in this field and are fully-informed as regards all matters relating to construction variables and technology.

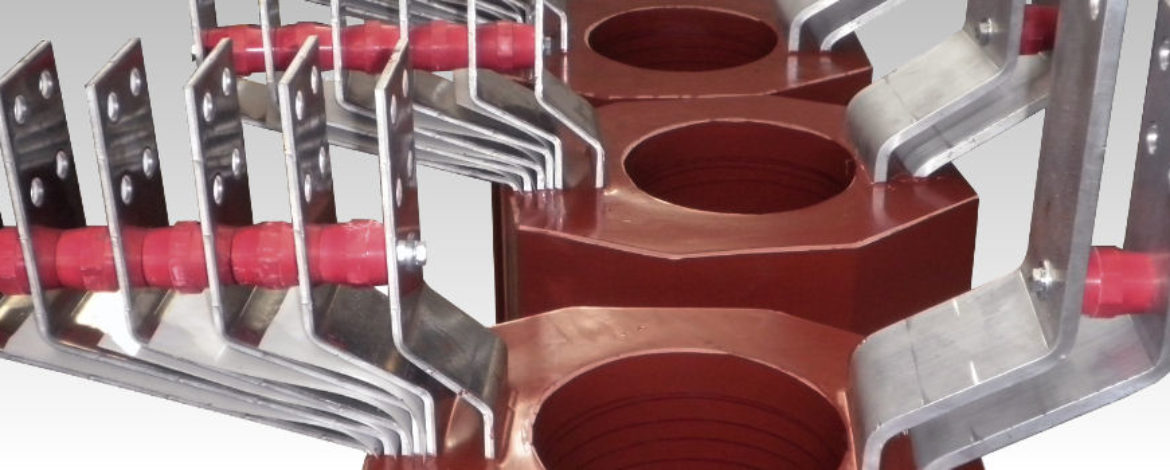

Accessories

Pressure pads and electronic temperature-detection / control devices.

Customized outlets

The customer's logo can be engraved in the coil terminal section.

Self-extinguishing capacity

On request, we can supply coils compliant with class F1 (cf. CEI 14-8, Appendix B).

Prices

Prices are determined in budgetary proposals drawn up in accordance with required data.

Testing

On request, the coils are supplied with a partial discharge certificate.

Guarantee

The coils are guaranteed for 24 months from the date of delivery.

Production process in 3 steps

The latest technology is used in our production processes to suit all needs and obtaining products complaint with very high quality standards.

Technical data

The client must provide us with all dimensional and technical parameters.

Production

Production is carried out according to the client's technical specifications.

Control procedures and warranty

Products are subject to specific control procedures and provided with a warranty.